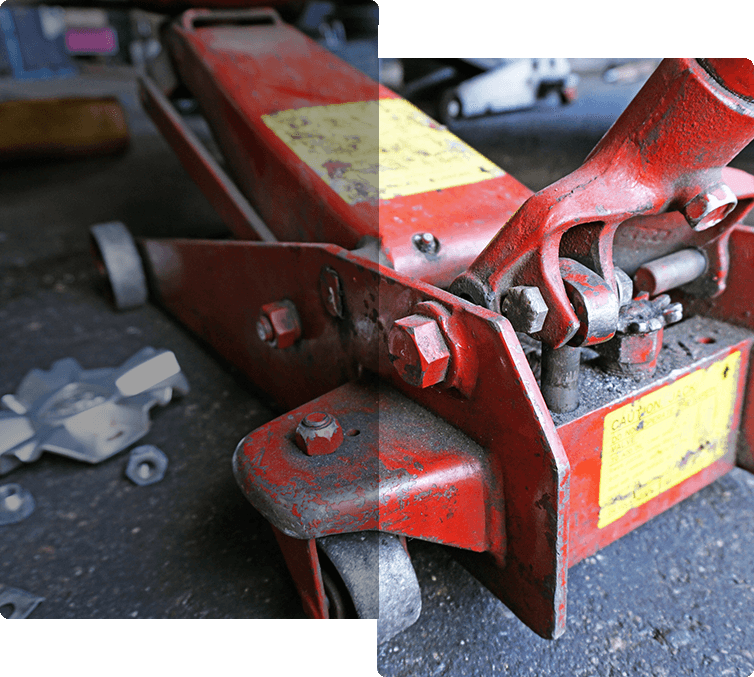

Hydraulic jack repair

Hydraulic jack repair

To withstand rough, demanding modern conditions, jacks, hydraulic driven jack equipment, and lifting arrangements must be sturdy, solid, and should be made using the highest quality materials. Whether working with automotive jacks and shop equipment or railroad tighten lever jacks, all arrangements should have the capacity to bear brutal conditions and extreme usages.

At Redex, we offer competitive valuing on new equipment and customized designing, however we additionally commit our aptitudes to hydraulic driven jack maintenance and full repair services. Our group can build interesting layouts, refresh a wide range of frameworks, and source top notch parts for the requirements of any shop.

We understand that repairing your hydraulic powered jack can be an overwhelming assignment. Complex frameworks require extensive knowledge and the best possible apparatuses to make repairs that are both safe and enduring. Choosing a specialist for repairs requires cautious thought to guarantee that your framework is returned to full service after repairs are made. Quality parts are likewise a necessity for successful repairs. Parts produced using the best possible materials will give your hardware the longest life and help to limit cash lost on repairs and down time.

INDUSTRIES AND APPLICATIONS

Intended for compact lifting to help substantial burdens, jacks are basic for any material handling processes in shops. Auto jacks, bed jacks, house jacks, whisky jacks, floor jacks, railroad jacks, screw jacks, carport jacks, farm jacks, and industry-specific jacks are some of the regular varieties of the mechanical jack design.

OUR FACILITY & CAPABILITIES

The Redex group can assess jacks nearby at our shop or at your office to decide the best repair,

remaking, or replacement solutions for your application.

Our office in UAE has a completely equipped repair and testing office, in addition to a total machine

shop and a huge stock of hydraulic parts. With cautious assessment, testing, and execution

diagnostics, the repair group can have your jack back on track rapidly and effectively.

Reach out to us today to learn more about our custom jack repair services and discuss how we can

help with your system.

BASIC HYDRAULIC JACK PROBLEMS

Despite their particular application, jacks regularly encounter similar sorts of issues, including:

- Jacks spilling oil

- Rams that won’t lift on service jacks

- Jacks floating down slowly or never totally extending

- Weakened frame construction, regardless of whether because of splitting, bowing, or breaking

- Wheels that squeak or don’t roll properly

- Jack handles kicking back

- Milky or frothy oil spilling from the gadgets

- Accidental overload/safety valve tripping on the jack

Assessing and disassembling the lift is regularly the most troublesome piece of overseeing jack

issues, yet the tears, cuts, and exhausted segments causing spilling and different issues are

sometimes inside the machine. Worn out seals, O-rings, nuts, rams, neoprene, and latches are

largely common guilty parties of defective or battling jacks and should be supplanted frequently —

particularly with heavy use.

Absence of grease, despicable liquids, and oil that has been tainted by water or different fluids can

likewise wear on a jack and cause possible failure.