Hydraulic seal fabrication

Hydraulic seal fabrication

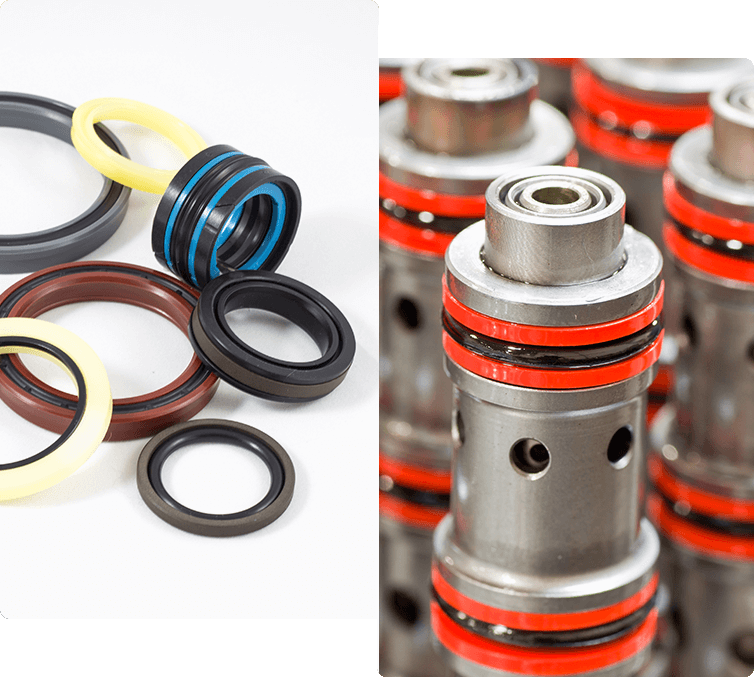

Hydraulic seals are a vital part of most pressure driven hydraulic frameworks. Typically made of some kind of delicate, adaptable elastomer that gives remarkable water and air fixing capacities, hydraulic seals are ring-formed and basically intended to wipe out or restrain the spillage of liquid moving inside a hydraulic or pneumatic framework. Hydraulic seals likewise also play important role in barring contaminants from and fittingly pressurizing general hydraulic system.

Production

Hydraulic seals are by and large produced using elastomers, natural and synthetic polymers, which have powerless atomic attraction and exceptionally versatile properties. Two noteworthy hotspots for hydraulic seals are rubber and plastics (including PTFE, for example, Teflon, and polyurethane). Other elastomer materials used to create seals incorporate butadiene, nitrile, butyl, and silicone. Seals made with these and other elastomeric materials are normally created through expulsion, in spite of the fact that Teflon seals are sintered in a stove from a powder form.

Seals may likewise be produced using non-versatile materials, for example, felt and leather. Some specific kinds of hydraulic seals (e.g. fortified seals) are produced using metallic materials (like brass, bronze, aluminium, carbon steel, and stainless steel). The majority of the metal materials used to make seals might be plated or galvanized for added oxidation quality. The attachment between the elastic material and metal of a reinforced seal is made by means of chemical bonding.

Major Types and Operations

Hydraulic seals are frequently found in water driven chambers, the mechanical actuators that change hydraulic pressure (from oil, water, or another pressurized liquid) into unidirectional power for agriculture and forestry service vehicles, construction equipment’s, and comparable systems.

Generally, hydraulic seals are situated on the barrel head, on the pole shaft, or in the cylinder. In these positions, seals shield liquid from spilling past the interface between the pole and head, from spilling to the outside of the chamber, and from streaming over the cylinder.

Hydraulic seals are divided into two main groupings: static and dynamic.

Static seals are ordinarily situated in grooves and other confined spaces, where they act as gaskets. In this unique situation, the term gasket refers to a mechanical seal that fills the space between at least two mating surfaces that don't have any movement amongst them and is held in place by weight connected by the fixing of jolts. To accomplish a protected seal, hub static seals must be crushed between their upper and lower surfaces. Spiral static seals, then again, achieve a similar thing when they are packed between their inward and external surfaces.

Dynamic seals, which are otherwise called shaft seals, seal holes between two surfaces that do share relative movement. Sorts of movement they work in between include reciprocation, oscillation, and rotation.